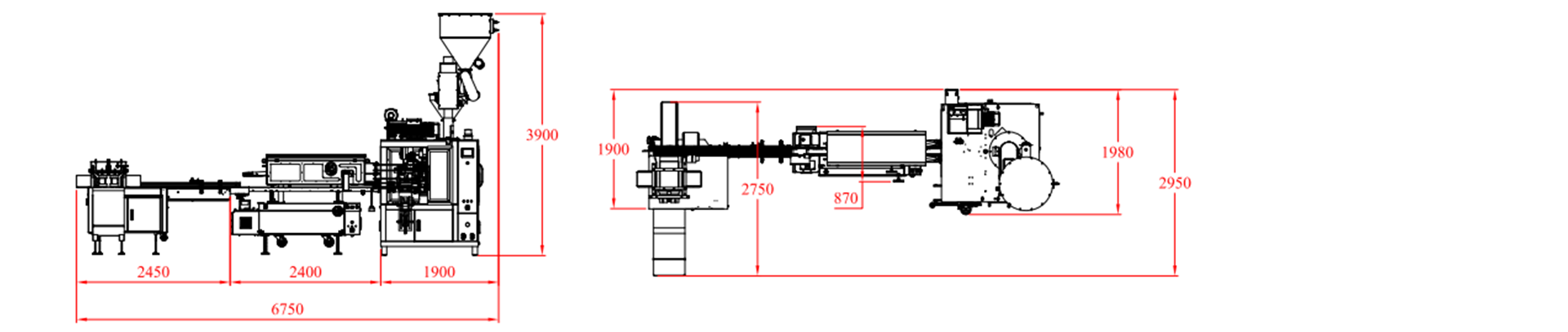

SAM FPM 155 New Model Fully Automatic Filling and Packaging Line automatically receives and fills flat-bottomed ready-made paper packages. The filled packages move towards the bag closing machine on the band. In the bag closing machine, the excess paper is cut, the first fold is made, the last fold is made with hot glue and it comes out of the machine with the mouth closed. The dates of the packages coming out of the bag closing machine are automatically discarded and the packages go to the counter machine for grouping before baling. The packages are grouped according to the kg unit and the baling process is realized by pushing the paper bag attached to the mouth of the machine by the operator with a piston.