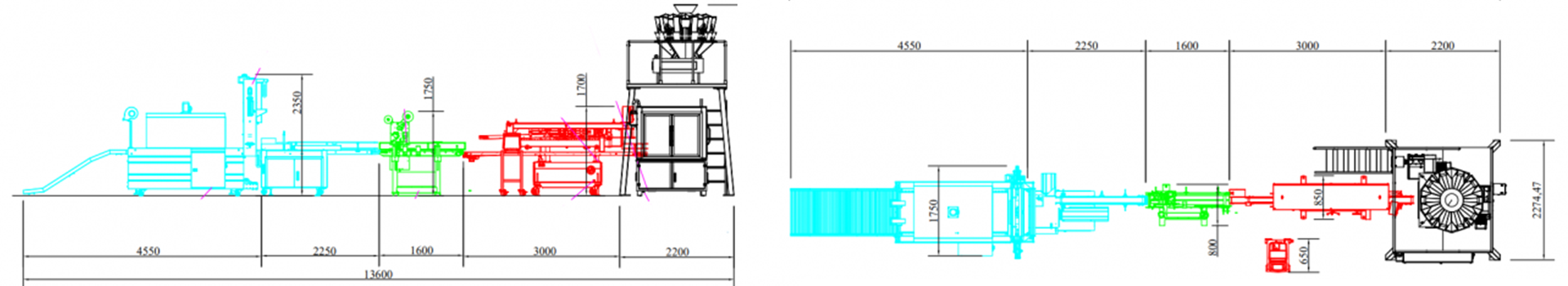

SAM FPM 125 Fully Automatic Tea Filling and Packing Line automatically takes and fills flat-bottomed ready-made paper packages. The filled packages move towards the bag closing machine on the band. In the bag closing machine, the excess paper is cut, the first fold is made, the last fold is made with hot glue and it comes out of the machine with the mouth closed. The dates of the packages coming out of the bag closing machine are automatically discarded and the packages are labeled by moving towards the labeling machine. Finally, the labeled packages move towards the automation shrink machine. In the shrink machine, the packages are grouped and shrinked.